If you have any questions about this equipment, write to us and our manager will be happy to answer you!

Milk Taxi

Features of the equipment "Milk Taxi"

Dairy equipment (a mobile milk pasteurizer) is a special mobile device that allows you to prepare, pasteurize, deliver and distribute dried and whole milk for calves. Using a milk taxi, it is possible to efficiently mix the milk replacer (the presence of a direct-drive mixer), pasteurize milk, deliver the resulting product using a powerful electric drive, dispense milk and milk replacer with the required preset portions (accuracy up to 0.01 kg).

Milk taxi is the best equipment for modern dairy complexes. This device allows for excellent calf health, lack of diarrhea, vitamin deficiency, mineral deficiency.

The purpose of the milk taxi

- mixing and heating the milk mixture to the set temperature;

- automatic delivery of milk mixture to the location of calves due to electric drive;

- supplying a predetermined amount of the mixture in the tank by means of a pump that is started by pressing a single button;

- pasteurization, ensuring the correct and sterile preparation of the milk mixture;

- the presence of many options like a heat exchanger (maintains a predetermined temperature of the milk), a mixing device, automatically turn on and off pasteurization and cooling, and a bottling system.

The mechanism of functioning of a milk taxi

- Using a mixer, the milk mixture is prepared, after which the finished product is heated to a temperature set by a specialist.

- Using a pump, the exact dosage of the milk mixture is supplied to the prepared containers (buckets).

The pasteurization function guarantees the supply of pure whole milk to the calves, without the slightest risk of developing diseases.

The main advantages of using a dairy taxi

- Milk taxi is highly mobile, as the presence of large wheels makes it easy to move equipment to the right place. Additionally, the device can be equipped with an electric drive for the chassis.

- It is highly stable, which is especially important during turns, due to the optimal position and size of the wheels.

- Using one mixer drive, you can gently mix whole milk or intensively mix milk replacer powder (depending on the selected program).

- Possibility of additional equipment heated (over 150 liters). Interval mixing eliminates the risk of burning the mixture. There is a possibility of a twofold increase in heating.

- Possibility of additional equipment with a metering gun and a cordless milk pump. Setting the right amount of mixture is done with one touch of the gun lever.

- The presence of three memory buttons located on the control panel of the equipment, which allow you to set three different volumes of servings, which is very convenient in the presence of calves of various groups.

- The presence of a simple and convenient washing program.

SPECIFICATIONS

| Overall dimensions of installation: | |

|---|---|

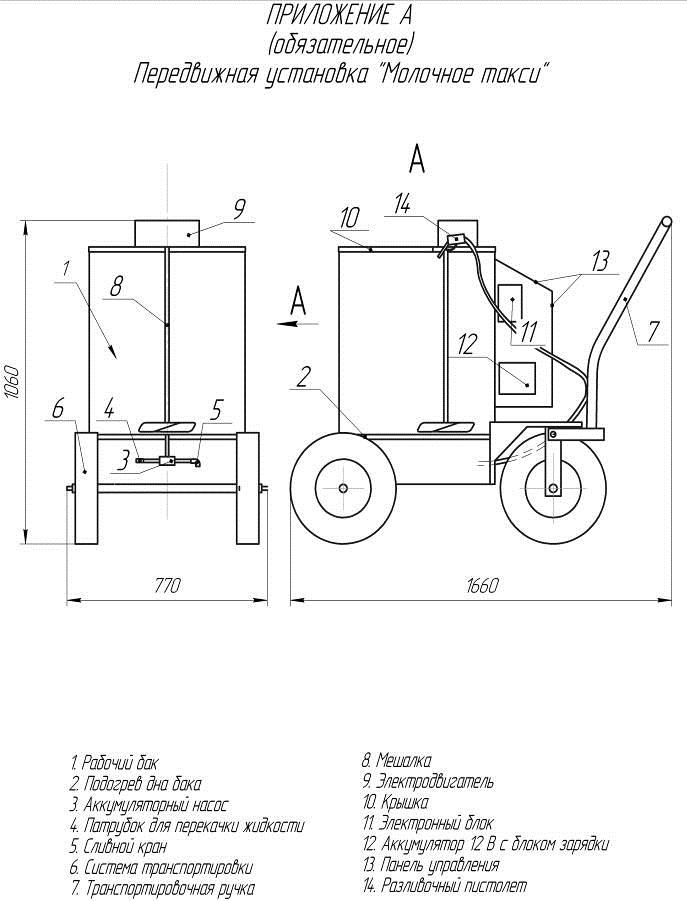

| length X width X height mm | 1660 х 770 х 1060 |

| Loading volume, l | 150 л |

| Mix heating temperature, ° С | 38 |

| Mixer rotation speed, rpm: | |

| mode I | 700 |

| mode II | 1500 |

| Heater power, kW | 2,5 |

| Mains Supply Current | AC |

| voltage, V | 220 |

| frequency Hz | 50 |

| Power consumption, kW / h | 2,9 |

| Installation weight, kg | 60 |