If you have any questions about this equipment, write to us and our manager will be happy to answer you!

Creamer for destruction of biological waste

Target usage of the creamer

The main objective of the equipment is the thermal destruction (neutralization) of various kinds of biological waste, including the mortality of birds and animals, laboratory materials, as well as slaughterhouse waste, and others. The cremator is used in the conditions of communal and agricultural facilities, industrial and veterinary institutions, as well as many other organizations whose activities include the destruction of organic waste. In addition, the equipment is capable of operating with a burner device using liquid or gaseous fuels.

Design features of the creamer

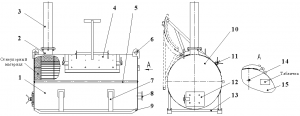

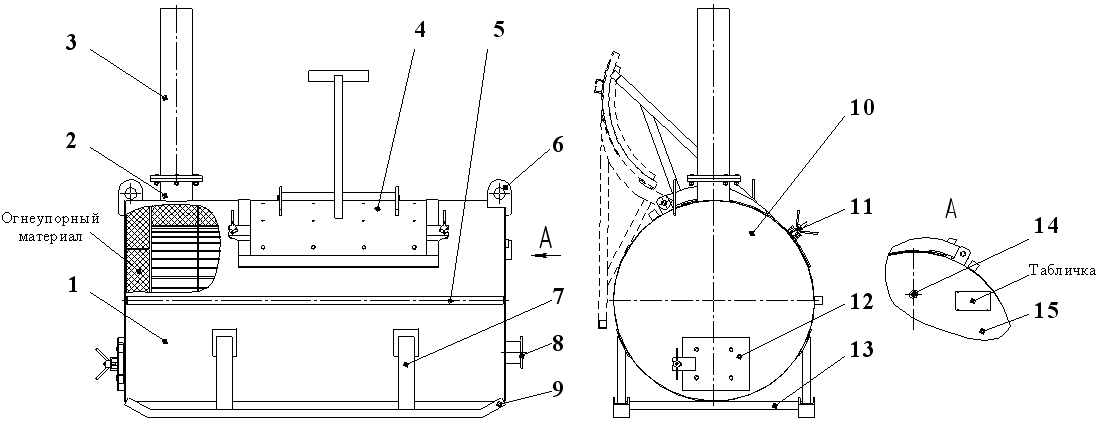

This equipment includes the following structural elements:

- combustion chamber;

- control automation cabinet equipped with a pyrolytic sensor;

- loading hatch;

- hatch for cleaning the device and the chimney.

When the burner starts up, the in-chamber temperature is accordingly brought to the operating value, and its subsequent support is provided automatically. To control the temperature inside the camera, a sensor is provided. The equipment cools naturally.

All cremators are airtight and heat resistant. The material from which the equipment is made is heat-resistant steel. Inside, each cremator is coated with a refractory, temperature-holding material, which allows you to maintain a certain temperature directly in the chamber, and also eliminates the risk of excessive heating of the outer surface of the combustion chamber itself. Ready-made cremators are also coated with silicone heat-resistant anti-corrosion enamel.

- - shell;

- - chimney pipe;

- - chimney;

- - manhole cover;

- - amplifier;

- - transport eye;

- - lateral support;

- - burner flange;

- - longitudinal support;

- - end wall;

- - clamp;

- - door;

- - transverse support;

- - thermocouple fitting;

- - end plate.

Using the cremator control cabinet it is possible to:

- Get the burner ignited and subsequent control over the operation of the burner is ensured according to the temperature level (for economical fuel consumption, the burner shuts off when the set temperature is reached);

- The burner fan operates according to the temperature level (in order to eliminate the risk of burner damage due to high temperature, to maintain combustion during a pause, to eliminate the likelihood of running hours).

Availability of output relay signals:

- the ability to control the ignition of the burner according to the temperature level;

- the ability to control the operation of the burner fan according to the temperature level;

- the presence of an alarm.

The controlled parameters:

- temperature level in the combustion chamber;

- burner operation according to temperature level;

- the possibility of blocking the burner;

- burner fan operation according to temperature level;

- the possibility of an emergency shutdown of the circuit breakers of the burner itself and its fan, as well as the cremator control cabinet;

- cremator operation time.

Supply voltage 220V +10/-15%, 50 Hz

Terms of exploitation

- working temperature -200С…+500С

- relative humidity 30 ... 80%

Level of protection no less than IP43

Controlled parameters:

- temperature in the combustion chamber

- burner operation according to temperature level;

- burner lockout;

- burner fan operation according to temperature level;

- emergency shutdown of burner protection circuit breakers, burner fan and cremator control cabinet;

- cremator work time.

Relay Output Signals:

- burner ignition control by temperature;

- burner fan temperature control;

- alarm.

Our company is ready to manufacture equipment in accordance with the individual needs of the buyer (according to the specific volume of loading, burning rate, type of fuel).

Cremators

| Model | KR-50 | KR-100 | KR-200 | KR-300 | KR-500 | KR-1000 | |

| Maximum load, kg | 50 | 100 | 200 | 300 | 500 | 1000 | |

| Installation weight, kg, no more | 400 | 900 | 1200 | 1500 | 2500 | 3500 | |

| Габаритные размеры, мм, не более:- ширина- длина — высота до верхней точки дымовой трубы | 900*2000*1900 | 1000*2250*2000 | 1100*2250*2100 | 1200*2500*2100 | 1300*2750*2200 | 1400*3300*2300 | |

| Sizes of a loading hatch, mm | — | 700х390 | 800х492 | 930х492 | 1400х650 | 1858х930 | |

| Внутренний диаметр дымовой трубы, мм, не менее | 100 | 125 | 150 | 200 | |||

| Weight of ash residue, kg, no more | 5 | 8 | 10 | 15 | 25 | 50 | |

| Refractory gasket | not | Yes | Yes | Yes | Yes | Yes | |

| Thermal properties of a laying, ºС | not | 1650 | 1650 | 1650 | 1650 | 1650 | |

| Lamborghini burner diesel l / h (max combustion) | 5-7 | 5-7 | 5-7 | 7-9 | 8-10 | 12-14 | |

| Burner thermal power, kW | — | 36-101 | 36-101 | 36-101 | 59,3-124,5 | 83-176 | |

| Burning power, kg / h | 20-25 | 25-40 | 30-45 | 30-50 | 35-55 | 40-70 | |

| Liquefied gas, l / h | — | 7-8 | 8-9 | 8-9 | 13-14 | 13-14 | |

| Natural gas, m3 / h | — | 5-6 | 6-7 | 6-7 | 8-9 | 8-9 | |

| Average diesel consumption, l / h (experienced) | 3,5-5 | 3,5-5 | 4-7 | 4-7 | 7-10 | 7-10 | |

| Burning time at full charge, hour | 2-3 | 2-3 | 4-6 | 5-7 | 12-16 | 14-20 | |

| Power supply | AC mains 220V / 50Hz / 20A | ||||||

| The average temperature in the combustion chamber, ° C | 760-870 | ||||||

| warranty | 1 year | ||||||

- GOST certificate of conformity for cremator

- cremator environmental certificate of conformity

- GOST certificate of conformity for the burner

- cremator passport

- burner passport

- wiring diagram

- cremator

- Lamborghini burner

- automation control cabinet

- THA thermocouple

- chimney

- fuel tank with fuel line (supplied with diesel burner)

- package of documents

In addition, if the client has the desire, the cremator can be equipped with a burner operating on waste oil.

At 100% payment, we offer a flexible system of discounts!

* - The price does not include delivery, installation and commissioning.

Крематоры в ассортименте каталог 06.2023 —

View catalog