If you have any questions about this equipment, write to us and our manager will be happy to answer you!

Pasteurization bath

Bath tank: model OPA-600, capacity 630 l / h at heating elements, including a control panel at a cost of 372,000 rubles per unit.

Destination

Milk is pasteurized with the help of the VDP bath-tank brand, dairy products and sourdough are produced by dairy enterprises.

Product Technical Features:

- Volume 630 L

- The frequency of rotation of the mixer 35 ± 5 rpm

- Maximum heating within 90 ºС

- Maximum cooling cooling 5-6 ºС

- Range of steam pressure inside the steam line 0.01 - 0.03 MPa

- Drive and type of electric motor asynchronous

- Maximum power 0.18 / 0.55 kW

- Frequency of rotation of 700/1450 rpm

- Required voltage 380V/50 frequency, Hz

Dimensions within, cm:

- Diameter 140

- Height 175

- По массе, кг (до) 32

Delivery is up to ten days.

Design features and mechanism of work

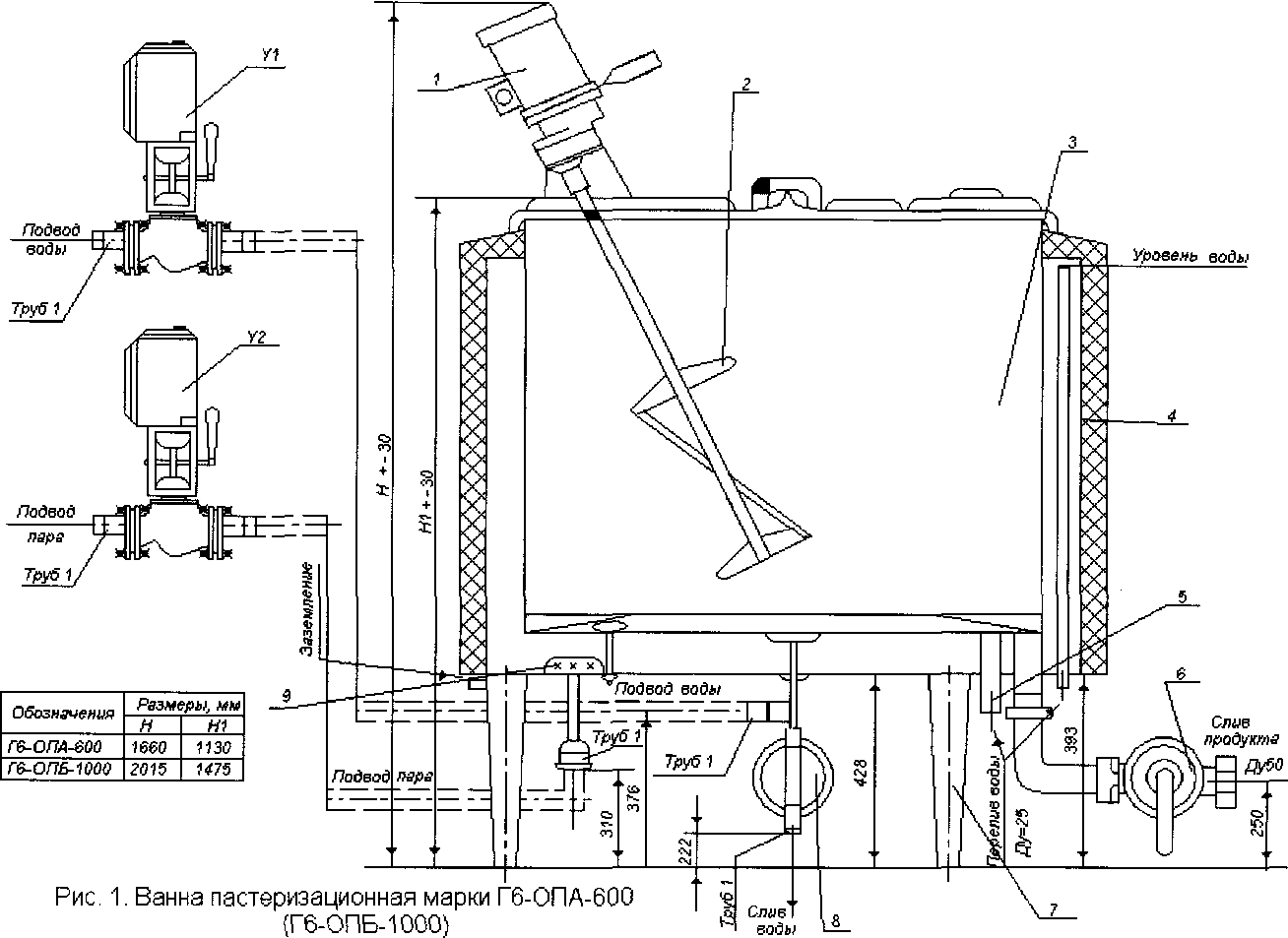

The following items are included in the package of the tank-tank:

- internal tank (bath) - 3

- outer double-walled enclosure - 4

- a steam distribution head located under the inner bath, to which the heating elements are connected or steam is supplied by a pipe - 9

- a nozzle by means of which water is drained from the interwall space of the outer bottom - 8

- overflow pipes supporting the water level in the interwall space - 10

- a cover including two halves, one of which can be easily lifted and lowered manually. When the cover is lifted, the agitator drive is switched on by the limit switch. The second part of the cover with three bolts attached to the body of the bath.

The bathtub is equipped with three supports, and can be attached to the floor or foundation with anchor bolts. The structural features of the VDP are similar to the G6-OPA (OPB), the difference lies only in the location of the drain pipe.

The heating of the direct product occurs due to the heating of cold water, poured into the interwall space, due to the heating elements or steam. For optimal heat transfer, the mixer constantly mixes the product. Product cooling is achieved by filling the interstitial space of the bathtub with chilled water.