If you have any questions about this equipment, write to us and our manager will be happy to answer you!

Milk line

Milk line: main functions and features

Thanks to a correctly selected, safe for animals milk pipe system, it is possible to effectively automate the main business processes in the farming business of any scale. The assortment of StandardMoloko LLC includes high-tech complexes of dairy equipment that fully comply with strict quality standards and modern requirements.

Our equipment allows us to solve the following current tasks:

- — provides machine milking in conditions of different keeping animals;

- — filters the manufactured products;

- — transports milk to a specially designed container.

Linear milk line: a professional milk collection solution

Each model of the milk pipeline has an individual scheme and configuration, is made of different materials and is designed for a different number of animals. Our catalog offers many equipment options suitable for any needs and scale of the farm.

The company "StandartMoloko" offers milk pipelines:

- - for 50 animals (for small animal husbandry);

- - for 100 animals (for medium animal husbandry);

- - for 200 and more animals (for large animal husbandry).

The main components of all milk pipelines

- The milk defroster. The main material this element is made of is food grade plastic with protection against mechanical damage. The milk flask consists of a sanitary valve, a filter element, electronic level sensors and a pump.

- Milk pump. The component is mainly made of stainless steel, due to which its design becomes as strong and reliable as possible.

- Vacuum installation.

Milk pipelines from StandardMoloko LLC: efficiently, profitably, safely

Innovative developments. Thanks to the latest technology to create the most comfortable conditions for animals and ensure maximum efficiency of current processes.

Automated milking control. Instruments that allow you to control processes are ergonomic, compact in size and light in weight, creating the most convenient conditions for use. Among other things, they are equipped with indication of milk yield and clear visualization functions, which simplifies the work of specialists.

Quality milk pipe is the price of success. The advanced equipment from our company is not only highly efficient and durable, but also one of the most affordable solutions on the market.

Wide customer base. The company has significant territorial coverage, thanks to which farms with any location can easily order the right milk pipeline (Izhevsk and other settlements of the country).

Features of our milk pipelines

Close cooperation with specialists of the Izhevsk Agricultural Academy allowed us to develop such a complete set of milk pipelines that eliminates animal injuries, increases productivity and ensures full compliance of milk quality with all state standards. An additional advantage of the equipment is its simplicity and accessibility in use and maintenance.

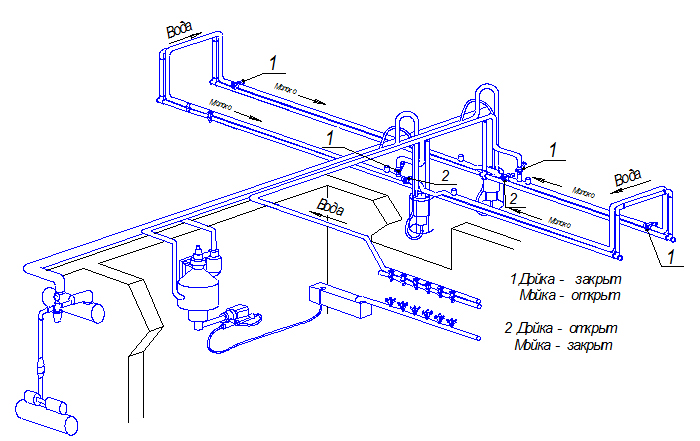

According to the milk movement system, the devices can be ring and dead ends. We prefer a deadlock system that:

- - does not need devices for raising branches;

- - allows you to keep an individual record of each specialist’s milk yield (one electronic counter for 50 goals);

- - provides the optimal distance between the dispenser and the last milk-vacuum crane (up to 30m), preventing the formation of milk balls in the milk line.

The equipment set also includes milking machines with pairing with a 300 ml collector from the Italian manufacturer INTERPULS, thanks to which optimal milking conditions are achieved that are safe for cows.

The stability of the vacuum is due to the following factors:

- - 40th diameter of the vacuum pipe installed on the stalls

- - 75th diameter of the main vacuum pipe;

- - 100-liter volume of the receiver;

- - a reliable vacuum regulator, the response interval of which is 2-3 seconds.

Our products are always available, and the equipment may vary according to customer requirements. Installation of the milk line takes 5-10 days.

Linear milk pipelines

For 100 heads of cattle: | Price |

| UDM-100 "Vanguard" (milk pipe stainless steel Ø52x1 mm; galvanized vacuum pipe. pipe Ø40, main vacuum line NPVH pipe Ø75 milking machines for pairwise milking INTERPULS, automatic flushing, водокольцевая вакуумная установка СН-60 А, водонагреватель на 200 л.) | |

| UDM-100 "Vanguard" (молокопровод нерж.Ø52х1 мм; вакуумпровод труба НПВХ Ø50 , доильные аппараты с пульсатором INTERPULS, водокольцевая вакуумная установка УВВ 70/1, водонагреватель на 200 л.) | |

For 200 heads of cattle: | |

| UDM-200 "Vanguard" (milk pipe stainless steel Ø52x1 mm; vacuum pipe galvanized pipe Ø40, main vacuum pipe NPVH pipe Ø75, pairing milking machines INTERPULS, automatic flushing, водокольцевая вакуумная установка СН-60А – 2шт, водонагреватель на 450 л.) | |

| UDM-200 "Vanguard" (молокопровод нерж.Ø52х1 мм; вакуумпровод труба НПВХ Ø50, магистральный вакуумпровод НПВХ труба Ø75, доильные аппараты с пульсатором INTERPULS, водокольцевая вакуумная установка УВВ 70/2, водонагреватель на 200 л.) | |

| UDM-200(молокопровод нерж.Ø52х1 мм; вакуумпровод, труба ПВХ Ø40, магистральный вакуумпровод НПВХ труба Ø75, доильные аппараты Майга , водокольцевая вакуумная установка УВВ70/2) | |

*Цены указаны с учётом НДС, монтажа и доставки.

Options and specifications

UDM-200 milk pipeline (Vanguard)

Number of cows served | 200 |

The number of milking machines in the milk line | 12 pcs |

Type of pulsators in milking machines | Pneumatic INTERPULS L 02 (paired milking pr-v Italy) |

Type of collector of milking equipment | Paired milking 300 cm cube |

Type of teatcup rubber for milking machines | GASCOIGNE MELOTTE (Black) 0/528 |

Individual metering device (control milking) IU-1 | 6 pcs |

Material of the main milk pipeline | Stainless steel, DIN 11850, 366 м. |

Outside diameter of milk line, mm | 52 х 1 |

Flushing milk material | Stainless steel, DIN 11850 |

Diameter of flushing milk line, mm | 52х 1 |

Pressure milk material | Stainless steel, DIN 11850 |

Type of milk-vacuum cranes | Combined |

Milk supply to the cooler tank | PVC hose 10m. |

Vacuum installation water ring SN-60A | 2 |

Type of vacuum regulator | ADM. 08.000 (4000 l / min) |

Number of vacuum gauges | 3 |

Material and diameter of the main vacuum line | Plastic, outer diameter 75 mm. |

Material and diameter of the vacuum pipe in the barn | Galvanized pipe Ø40 mm, 312 m. |

Type of milk collector | High-impact food grade milk collection unit V=65 л |

Number of milk dispensers | 4 psc |

Electronic counter of milk milk, UUM-2 (accounting from each milkmaid) | 4 psc |

Milk tube filter | 1 psc |

| Milk pump NMU-6 | 1 psc |

| Water heater 350 l | 1 psc |

Stainless Steel Dust Collectors | 4 psc |

Bathtub for the washing solution from stainless steel V = 180 l. | 1 |

Stand for washing milking machines, pcs | 2 blocks of 6 nozzles |

| Washing machine | 1 psc |

The device for blocking the ingress of detergent into the milk cooling tank | Yes! |

Injectors for creating turbulence | Air injector |

A set of plumbing products for connecting water supply | Plastic pipe wiring |

Power Supply Class | IP 65 |

Switchboard with automatic protection | Yes |

Cable routing in PVC pipes and cable channels | Yes |

Vacuum motor circuit breaker | Yes |

Kit for attaching pipelines to support poles and leash posts | 120 psc galvanizing |

Set of consoles and attachment of consoles to leash racks | Hot dip galvanizing 120 psc |

Metal clamps and hardware for fastening pipelines | 200 head kit |

Filter elements | 125 psc |

Wad foam | 10 psc |

Alkaline detergent 24 kg | 1 psc |

Acid Cleanser 24kg | 1 psc |

Milking machine for milking mastitis cows with a pair pulsator and a bucket | 4 psc |