If you have any questions about this equipment, write to us and our manager will be happy to answer you!

Pre tube milk cooler

What is it needed for:

It's no secret that the faster the milk is cooled, the slower the bacteria multiply, which helps preserve the quality of the milk. Mixing of morning and evening milking takes place painlessly.

Surely, many thought about instant milk cooling to 4 degrees Celsius, but the cost of cooling equipment, complex installation, maintenance, etc. stops. Equipment

just not cost effective for farm work. In the case of the pre-cooler, we do not get instant cooling, but we reduce the operating time of the tank by 2, or even 3 times.

The pre-cooler does not require complex installation, only a well with water is needed, which, most likely, already exists. Plus, the load on the compressor of the cooler tank is reduced;

much less is needed. The biggest plus is the cost of the equipment, it costs ORDER (10-15 times) cheaper. If necessary, this equipment can also be used when working with

ice water generator.

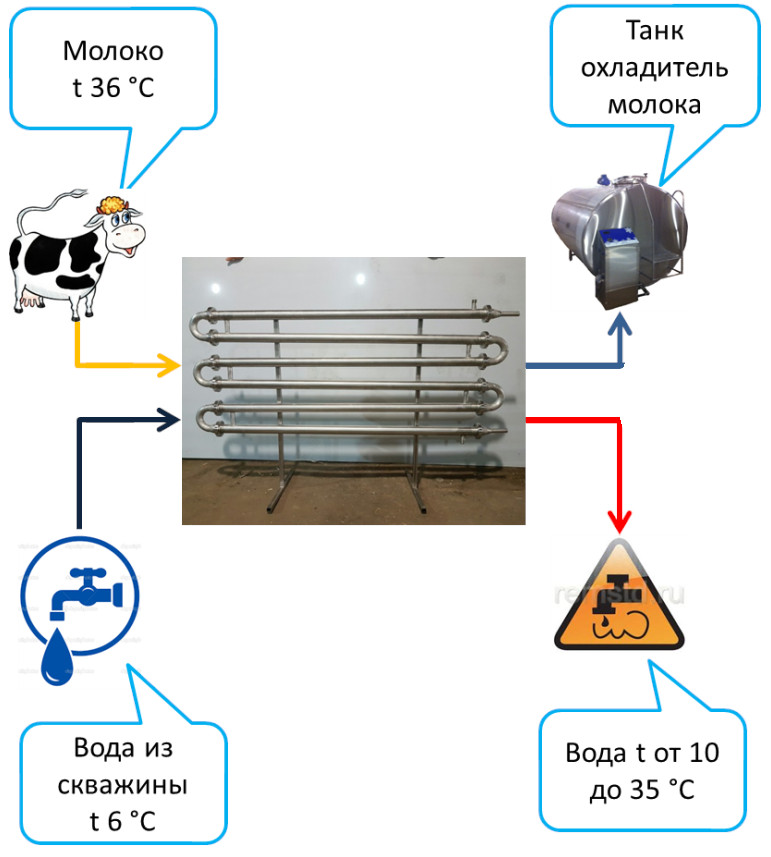

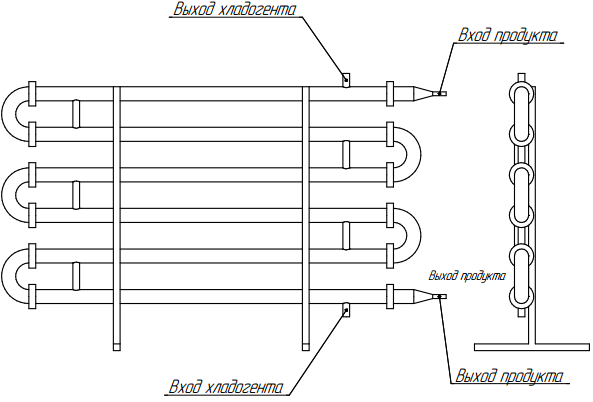

How it works (working principle):

The principle of operation of the milk precooler is quite simple.

From the milk pipeline, milk does not immediately enter the cooler tank, but is cooled by the counter flow of water from the well.

This allows the milk to be cooled to a temperature of 7 to 15 degrees Celsius (the temperature of the milk cannot be lower than the temperature of the water from the well).

To what temperature the milk should be cooled is determined by the customer.

The dependence is quite simple, the more water we are ready to spend on precooling, the lower the temperature of the milk will be.

What questions need to be answered in order to get a cost estimate:

- Milk pump productivity per hour;

- Water pump productivity per hour (maximum);

- Well water temperature;

- To what temperature should the milk be cooled (cannot be lower than

water in the well).

Summary table for models, prices and capacities of pre-coolers.

Precooler marking | Product pump | Specification | Price | ||||||

6000 l/h | 5000 l/h | 4000 l/h | |||||||

Drop in milk temperature at the outlet gr. C | Contour Qty, pcs | Contour length, cm | Power by area, kW / h | Product volume, l | Refrigerant volume, l | ||||

10-200 | 32 | 39 | 49 | 10 | 200 | 220 | 7,9 | 30 | 119 000,00 |

8-200 | 26 | 31 | 39 | 8 | 180 | 6,3 | 24 | 96 000,00 | |

7-200 | 23 | 27 | 34 | 7 | 158 | 5,5 | 21 | 86 000,00 | |

6-200 | 20 | 24 | 29 | 6 | 135 | 4,7 | 18 | 74 000,00 | |

5-200 | 16 | 20 | 24 | 5 | 113 | 4,0 | 15 | 63 000,00 | |

4-200 | 13 | 16 | 20 | 4 | 90 | 3,0 | 12 | 52 000,00 | |

3-200 | 10 | 12 | 15 | 3 | 68 | 2,4 | 9 | 40000,00 | |

2-200 | 7 | 8 | 10 | 2 | 45 | 1,6 | 6 | 29 000,00 | |

Prices are indicated in rubles.

The term of production is 14 working days.

Installation is not included in the price.

Maintenance is optional.

12 months warranty.

Delivery from a warehouse in Izhevsk by agreement of the parties.